The Role of API 650 Welding Inspection in Securing Code Compliance

Just How Welding Inspection Works: A Comprehensive Guide for Professionals

Welding evaluation plays an essential duty in guaranteeing the safety and security and reliability of bonded structures. It includes an organized strategy that consists of both aesthetic inspection and progressed screening approaches. Professionals have to familiarize themselves with essential requirements and guidelines controling the sector. Comprehending the typical problems that can arise throughout welding is essential. This overview will certainly explore these components in information, offering understandings right into the processes that copyright top quality and stability in welding.

Understanding the Relevance of Welding Examination

While several may ignore the importance of welding assessment, it plays a necessary role in making certain the stability and safety of welded frameworks. Effective welding assessment identifies possible defects and imperfections that can compromise architectural strength and cause disastrous failings. The inspection process includes various methods, such as visual evaluations, ultrasonic screening, and radiographic analyses, each contributing to the general analysis of weld quality.

In enhancement to securing the architectural integrity, welding evaluation guarantees compliance with market requirements and customer requirements. By ensuring that welds meet required tolerances and qualities, assessments aid keep the reliability and longevity of components in various applications, from building to aerospace. In addition, a rigorous examination procedure fosters a culture of high quality and liability amongst producers and welders. Eventually, welding assessment is not merely a procedural action; it is a critical technique that underpins the safety and security and efficiency of engineered systems throughout varied markets.

Trick Criteria and Regulations in Welding Evaluation

The foundation of efficient welding assessment hinges on adherence to developed guidelines and criteria. Various organizations, such as the American Welding Society (AWS) and the American National Standards Institute (ANSI), stated guidelines that assure high quality and safety in welding practices. Secret requirements, such as AWS D1.1 for structural welding and ASME Area IX for pressure vessels, give thorough standards for welding qualifications, assessments, and procedures. Governing frameworks, consisting of those from the Occupational Security and Health And Wellness Management (OSHA), required safety and security practices and worker securities in welding atmospheres. Conformity with these standards is vital for achieving regular weld top quality and minimizing the threat of failings. Additionally, worldwide criteria like ISO 3834 additionally enhance global consistency in welding assessment practices. Specialists need to stay educated about these laws to guarantee that their inspection approaches align with market assumptions and lawful demands, therefore protecting both employees and architectural honesty.

First Preparation and Visual Assessment Techniques

Effective welding assessment starts with a detailed pre-inspection list that ensures all essential problems are met before the real inspection happens. Following this preparation, visual defect identification plays a vital role in examining weld top quality, permitting assessors to detect problems such as fractures or improper combination. Together, these methods form the foundation for an effective welding examination process.

Pre-Inspection List

Prior to starting any welding examination, an extensive pre-inspection list is important to ensure that all required preparations are completed and that aesthetic examination strategies are efficiently utilized. Key aspects of this checklist consist of confirming the welding treatment requirements (WPS), ensuring all tools is adjusted and in great working problem, and verifying that the assessor possesses the required certifications. Additionally, it is important to review any previous inspection reports and to examine the job atmosphere for safety dangers. The inspector must additionally validate that all relevant documentation, such as product certifications and assessment records, is easily available. Completing this list helps to develop a solid structure for an effective examination procedure, improving the dependability of the outcomes acquired.

Visual Problem Recognition

An effective visual issue identification process starts with careful initial prep work and the application of recognized visual inspection techniques. Examiners must guarantee that the welding location is well-lit and tidy, as appropriate exposure is important for detecting defects. A detailed examination of the weld joint's surface area enables the identification of discontinuities, such as cracks, undercuts, or porosity. Assessors usually utilize devices like amplifying glasses or mirrors to improve their view of hard-to-reach areas. In addition, they ought to be familiar with the particular welding criteria and standards pertinent to the task. By sticking to these techniques, assessors can effectively recognize potential problems, protecting the integrity of the weld and conformity with sector criteria.

Non-Destructive Screening Methods: An Introduction

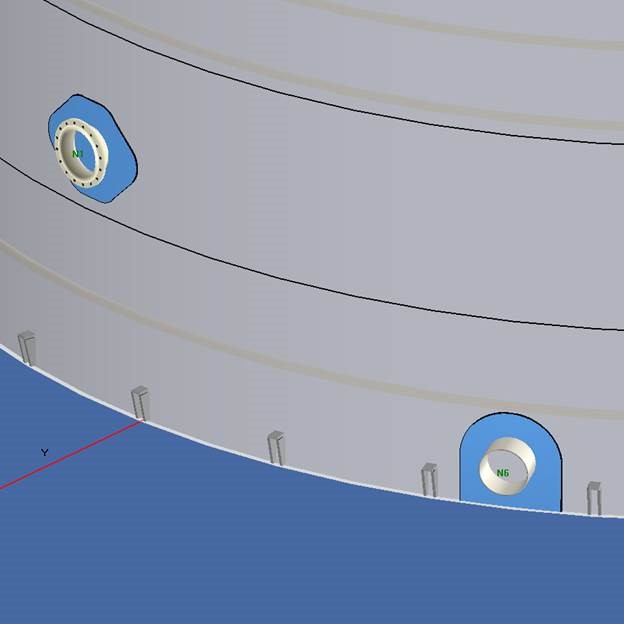

Non-destructive testing (NDT) approaches play a crucial duty in the welding examination procedure by making certain the stability and reliability of bonded structures without causing any type of damage (API 650 Welding Inspection). These strategies allow assessors to assess the quality of welds while preserving the elements being taken a look at. Typical NDT methods include ultrasonic screening, radiographic testing, magnetic fragment testing, and color penetrant testing, each offering unique benefits

Ultrasonic screening employs high-frequency acoustic waves to discover internal problems, while radiographic testing utilizes X-rays or gamma rays this hyperlink to imagine the inner structure of welds. Magnetic fragment testing discloses surface area and near-surface flaws by using an electromagnetic field and iron bits to the weld area. Color penetrant testing highlights surface-breaking imperfections with the application of a colored dye. With each other, these NDT approaches give crucial understandings right into weld top quality, allowing specialists to make informed choices regarding safety and security and compliance in welding applications.

Usual Issues and Their Effects

Determining usual problems in welded joints is necessary for maintaining structural honesty and security. Different problems can develop during the welding procedure, each bring prospective implications for the general performance check my site of the structure. Porosity, defined by little gas pockets within the weld, can weaken the joint and jeopardize its load-bearing capability. Cracks might establish because of thermal stress or inappropriate cooling, resulting in possible failure under stress and anxiety. Incomplete blend occurs when the weld steel does not completely bond with the base product, resulting in weak joints that might not endure desired loads. Damaging, where the base steel is worn down, can also reduce the efficient cross-section of the weld. Furthermore, excessive support can produce tension focus that might bring about failure. Recognizing these defects without delay allows for corrective actions, making certain the long life and dependability of welded frameworks in important applications.

Tools and Equipment Used in Welding Examination

Efficient welding examination relies upon a variety of specialized devices and equipment to ensure the quality and honesty of bonded joints. Essential tools look what i found include aesthetic examination devices, such as magnifying glasses and borescopes, which allow examiners to closely examine welds for surface problems. Non-destructive testing (NDT) techniques, such as ultrasonic testing, radiographic testing, and magnetic particle screening, are essential for identifying inner defects without damaging the material.

Dimension tools, including calipers and weld determines, help establish and evaluate dimensions conformity with requirements. Additionally, solidity testers evaluate the mechanical homes of bonded joints. Individual safety tools (PPE) is additionally important, safeguarding the safety and security of assessors while working in possibly unsafe settings (API 650 Welding Inspection). Each device serves a particular function, collectively boosting the performance of welding inspection and contributing to the reliability of finished jobs

Often Asked Concerns

What Qualifications Are Required to Come To Be a Welding Examiner?

To become a welding assessor, people usually need pertinent qualifications, such as AWS CWI or CSWIP, together with experience in welding processes, design principles, and knowledge of examination methods, security standards, and relevant codes.

Exactly How Commonly Should Welding Inspections Be Performed?

Welding examinations should be performed frequently, preferably at numerous task phases, including pre-weld, during-weld, and post-weld. Regularity may additionally depend on sector standards, task specifications, and the intricacy of the welds involved.

Can Welding Defects Be Fixed After Evaluation?

Yes, welding problems can usually be repaired after evaluation. Relying on the severity and type of flaw, ideal methods such as reworking or extra welding might be utilized to recover architectural integrity and security compliance.

What Industries Require Regular Welding Evaluations?

Various markets, including building, production, aerospace, and vehicle, need normal welding assessments - API 650 Welding Inspection. These examinations assure adherence to safety requirements and high quality control, lessening threats related to architectural stability and functional efficiency in welded elements

Exactly how Do I Pick a Welding Examination Solution?

To select a welding assessment service, one should consider qualifications, experience, qualifications, and sector track record. Furthermore, assessing customer testimonials and guaranteeing the service satisfies relevant criteria can assist guarantee quality evaluations and trusted outcomes.

While numerous might ignore the significance of welding assessment, it plays an important duty in guaranteeing the honesty and safety of bonded frameworks. Key criteria, such as AWS D1.1 for structural welding and ASME Section IX for stress vessels, give complete standards for welding examinations, procedures, and qualifications. Efficient welding examination begins with a complete pre-inspection list that assures all required problems are fulfilled prior to the real inspection takes place. Before beginning any type of welding examination, a comprehensive pre-inspection checklist is vital to guarantee that all needed prep work are finished and that aesthetic examination methods are effectively utilized. Non-destructive testing (NDT) techniques play an essential duty in the welding examination procedure by ensuring the integrity and reliability of bonded frameworks without creating any type of damage.